Reverse engineering is a term mechanical engineering, is used to summarize the process of reconstructing an existing object. When designing an object from scratch, an engineer will draw up a design specification and produce drawings from which the item is constructed.

With reverse engineering, the design engineer starts with the final product and works through the design process in the opposite direction to arrive at the product design specification. During the process, vital information about the design concept and manufacturing methods is discovered.

Reverse engineering is a term mechanical engineering, is used to summarize the process of reconstructing an existing object. When designing an object from scratch, an engineer will draw up a design specification and produce drawings from which the item is constructed.

With reverse engineering, the design engineer starts with the final product and works through the design process in the opposite direction to arrive at the product design specification. During the process, vital information about the design concept and manufacturing methods is discovered.

Reverse engineering enables the duplication of an existing part by capturing the component’s physical dimensions, features, and material properties. There is a wide range of reasons for reverse engineering an object, including:

- Legacy Components: For many components that were designed and manufactured years ago, there are no existing 2D drawings or 3D CAD data from which to reproduce the object. Here, reverse engineering is a vital means to gain information to recreate the product.

- Old Components: For many components that were designed and manufactured years ago, there are no existing 2D drawings or 3D CAD data from which to reproduce the object. Here, reverse engineering is a vital means to gain information to recreate the product.

- Design Development, Part Testing & Analysis: Through reverse engineering, a 3D product can be quickly captured in digital form and remodeled or analyzed in order to achieve improved design iterations.

- Competitor Analysis: Any organization can analyses competitor products through reverse engineering.

- Modern manufacturing: methods such as Additive Manufacturing rely on reverse engineering.

THE REVERSE ENGINEERING PROCESS:

To reverse engineer a physical product, an organization will typically acquire an example of the product in question and take it apart to examine its internal mechanisms. This way, engineers can unveil information about the original design and construction of the product.

When reverse engineering a mechanical product, you start by analyzing the dimensions and attributes of the product in question during this analysis, you make measurements of the widths, lengths, and heights of key components in the product, as these dimensions often relate to the product’s performance capacity.

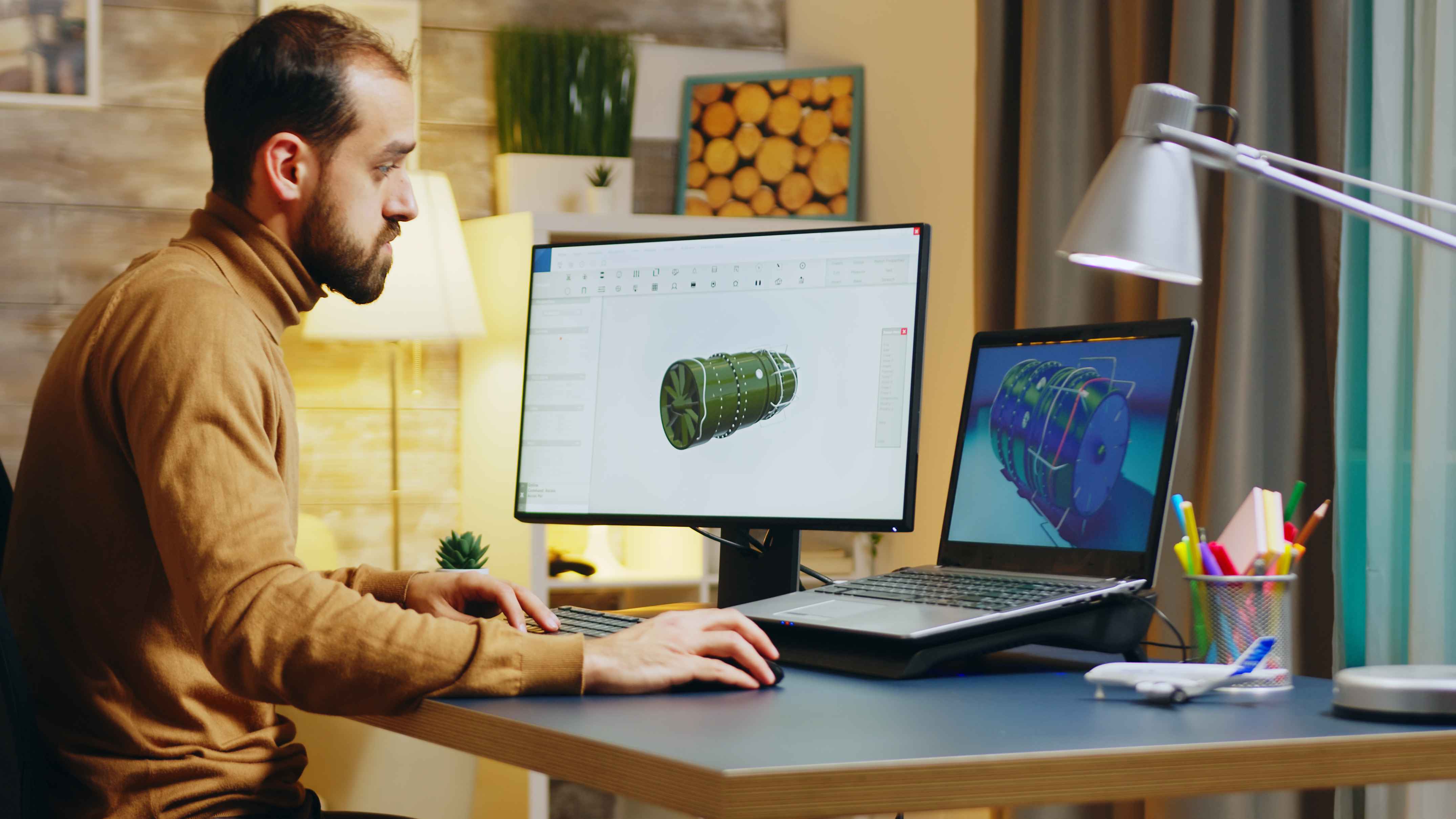

Today, some engineers use 3D scanning technologies to make these kinds of measurements. With three-dimensional scanners, engineers can gain accurate readings of the product’s specs and have this information automatically logged in their databases.

After all the pertinent information has been gathered and recorded, you can use this data to create computer-aided design (CAD) drawings for subsequent analysis and development. CAD drawings are digital two-dimensional and three-dimensional representations of the products, which you can use to analyze the product’s design.

Reverse engineering is often necessary for the development of computer parts due to the obsolescence of parts from prior years. For example, you might have one product with a unique innovation from two years earlier, but the manufacturer has since gone out of business. To link that innovation to a newer product for convenience and continuity’s sake, the engineering team will need to examine the obsolete product for its technological makeup.

In order to reverse engineer a PCB, technicians start by examining and identifying the various components of the board.

Before disassembly, the reverse-engineering team will photograph the board up close from the front and back to create a record of the board’s composition. Once the notes and images are collected, the engineers begin the process of deconstructing the board.

During disassembly, the team removes each part from the board, one after another. The parts must be set aside for safekeeping and organized in the order they were removed. This way, the board can be reassembled later on, if necessary. In cases where the objective is to replicate the design in question, engineers might test their ability to replicate the product by disassembling and reassembling an existing copy several times over.

As the team sets aside removed components, they take value measurements of key parts, including the capacitors and resistors. This step helps the team gain a greater understanding of the engineering that went into the original design. It also provides insight into how the board’s components work together to enable the PCB to function correctly.

With the various components removed from the old board, the team then draws up a list of the materials and the order in which they were placed on the PCB. The team will also scan the board’s trace pattern so that they can recreate it later.

The reverse-engineering team may then use the pieces at hand and the information collected to assemble a new board. First, they lay out a new board and then install the components in the same order used for the original PCB. Once assembled, the new board is run through a series of tests to determine its functionality. The team will digitally document the results of these tests for future study.

How to become reverse engineering:

1-Build a toolbox: gather as many tools as you can. Then, master the ones which you find useful or develop your own when you can do better.

2- Be methodical: with experience & practice you'll be able to come up with a set of steps to follow when reversing. These steps will certainly have to be updated with more experience but they'll surely help you find valuable information & data about your target.

3- Know your tools: always cross-reference the outputs of different tools (use multiple disassemblers,). Most tools have strengths and weaknesses and you must know them in order to understand what you're looking at.

4-documentation will in most, if not all, Any documentation related to the architecture, the tools you're using, the target application, the programming language, the compiler, it will help you understand how all the machinery manages to function.

Finally, Develop top programming skills: learn as many programming languages as you can: assembly (x86, ARM, 6502 ...), C, C++, Python, Haskell, and learn how to extract code patterns from low-level constructs - this is just a matter of experience & sharpness.

Then you can register on Ongineering website to find suitable freelancing work for you

Post Your Project

Post Your Project  Projects

Projects